All high-technology products that must go from a research lab to a commercial application face multiple challenges; but in India, these challenges are exponential. However, once you overcome them and see the product in its intended application, the joy is akin to that experienced by a mother holding a newborn baby. The excruciating pain which immediately preceded, and every other discomfort experienced for months before that, magically disappears in that moment.

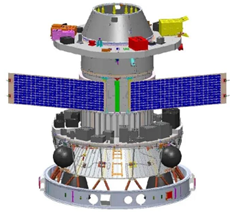

For me and my team, that defining moment was at 2:30 PM on Saturday, April 22, 2023, when ISRO’s PSLV C55 was launched with our very first indigenously developed MEMS gyroscope mounted on the satellite. A gyro - short form for a gyroscope - is a sensor that senses the rotational motion of the object it is mounted on, the same sensor that tells your smartphone to rotate its screen when you switch the handset setting from portrait to landscape orientation. It was an unbelievable feeling of joy - like holding a newborn baby. In this case, the pregnancy was 14 years long, and the planning of the conception even longer, since 1999!

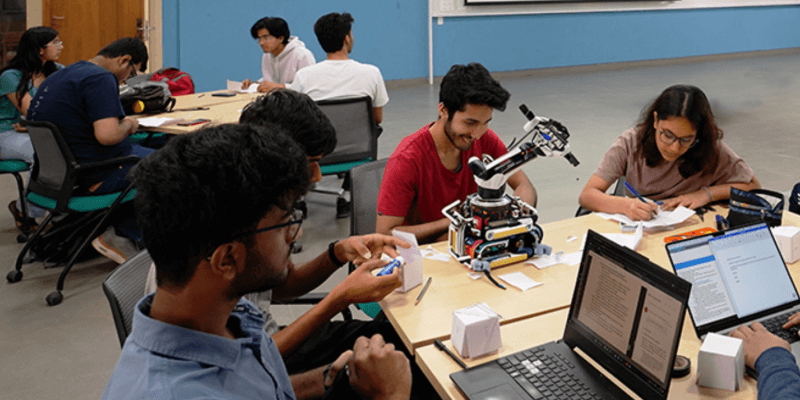

This journey began in the Spring of 1998, when I offered a new course on MEMS (Micro-Electro-Mechanical Systems) Technology for postgraduate students within the Department of Mechanical Engineering at the Indian Institute of Science, Bengaluru. The course was new for everyone, including me. I was completely smitten by this upcoming technology, and could foresee its potential and implications for India.

Persuasion and Pursuit

When I walked into the classroom, I saw a rather unusual student sitting on the front bench, a man perhaps in his late 50s or early 60s. He politely asked for my permission to attend as an unregistered student. After the class, he introduced himself as General Sundaram and shared his avid interest in the technology with me. Soon, I found out that he had just completed his stint as the Director of one of our most strategic DRDO labs. During the ensuing months, we exchanged several conversations about the course and the implications of this technology for India.

At the end of the semester, General Sundaram implored me to work on MEMS gyros, a project no one else in the country was willing to undertake. I did not find it exciting enough either, because by then at least one company from the USA had already launched a commercial MEMS gyro. One of the biggest challenges of working in India as a researcher always is to find a balance between front-line research pursuits and the imperatives of indigenizing an already-known technology.

General Sundaram could be extremely persuasive though. And thus began the journey of designing India’s first MEMS gyro in 2002. Three masters’ students graduated in the next four years with their theses on different aspects of MEMS gyros. In 2006, we tried fabricating our first gyro at the Semi-Conductor Laboratory (SCL), Chandigarh. Soon after however, the lab became unavailable due to a technology upgrade.

A Homegrown Triumph

Meanwhile, our designs matured and we enhanced our grip on the technology. In 2009, we approached a university lab in the UK to get our gyro designs fabricated. I sent my student, JP Reddy, to the lab in the UK to make the required modifications for conforming to the processes available there. We achieved partial success in the first run, but the lab quoted double the price for the next iteration. Fortunately for us, our Centre for Nano Science and Engineering (CeNSE) at IISc came alive in 2010 and just a year later, the most critical tool for gyro fabrication — the Deep Reactive Ion Etcher (DRIE) — also arrived there.

My brave-heart student, JP, took a stab at fabricating the device, rather than sending it to the UK. He was also working on his PhD on gyro development. Although he had no hands-on training, but the establishment of CeNSE with a National Nano-fabrication Centre (NNfC) helped. The Centre soon emerged as a landmark in the history of Indian higher education in science and technology, and a source of envy for universities globally.

JP worked on the DRIE for the first time and shattered the entire silicon wafer. Within a year, he fabricated the very first MEMS gyro which worked fabulously with comb-drives oscillating at several thousand cycles per second. Buoyed by this success, I travelled to VSSC, ISRO in Thiruvananthapuram and delivered a talk on MEMS gyros in 2013 to ISRO scientists and engineers within the Inertial Systems Unit.

Two years later, the ISRO unit asked me to develop a particular kind of gyro for them. I received a research grant and JP commenced working on the new gyro. JP finished his PhD, got a job at ISRO, and I continued working in my lab.

Intricate Tiny Structures

A MEMS gyro is not easy to fabricate. It uses very intricate tiny structures, generally made in silicon with microfabrication technology. The fabrication tolerance of a couple of microns (a single human hair diameter is about 80 to 100 microns) on the physical dimensions is rather tight and there can be absolutely no room for error in fabrication.

Finally, after 14 years in development, on April 22, 2023, when ISRO launched PSLV-C55 carrying the PSLV Orbital Experimental Module (POEM), it contained our MEMS gyro on board for its attitude control. I witnessed the live launch online and eagerly waited to receive signals from our gyro. The next morning, JP confirmed that “all is well”.

It is indeed hard to describe that feeling. This is the very first indigenous high-tech MEMS product that India has been able to design, develop, and deploy. Although it’s a tiny module in the satellite, it is nevertheless a giant leap in crafting sophisticated high-tech products indigenously in India.

This piece is authored by Prof. Rudra Pratap , Founding Vice Chancellor at Plaksha University.